VALUEFARM Containers

Modular, High-Yield Cultivation for Commercial Seaweed Production

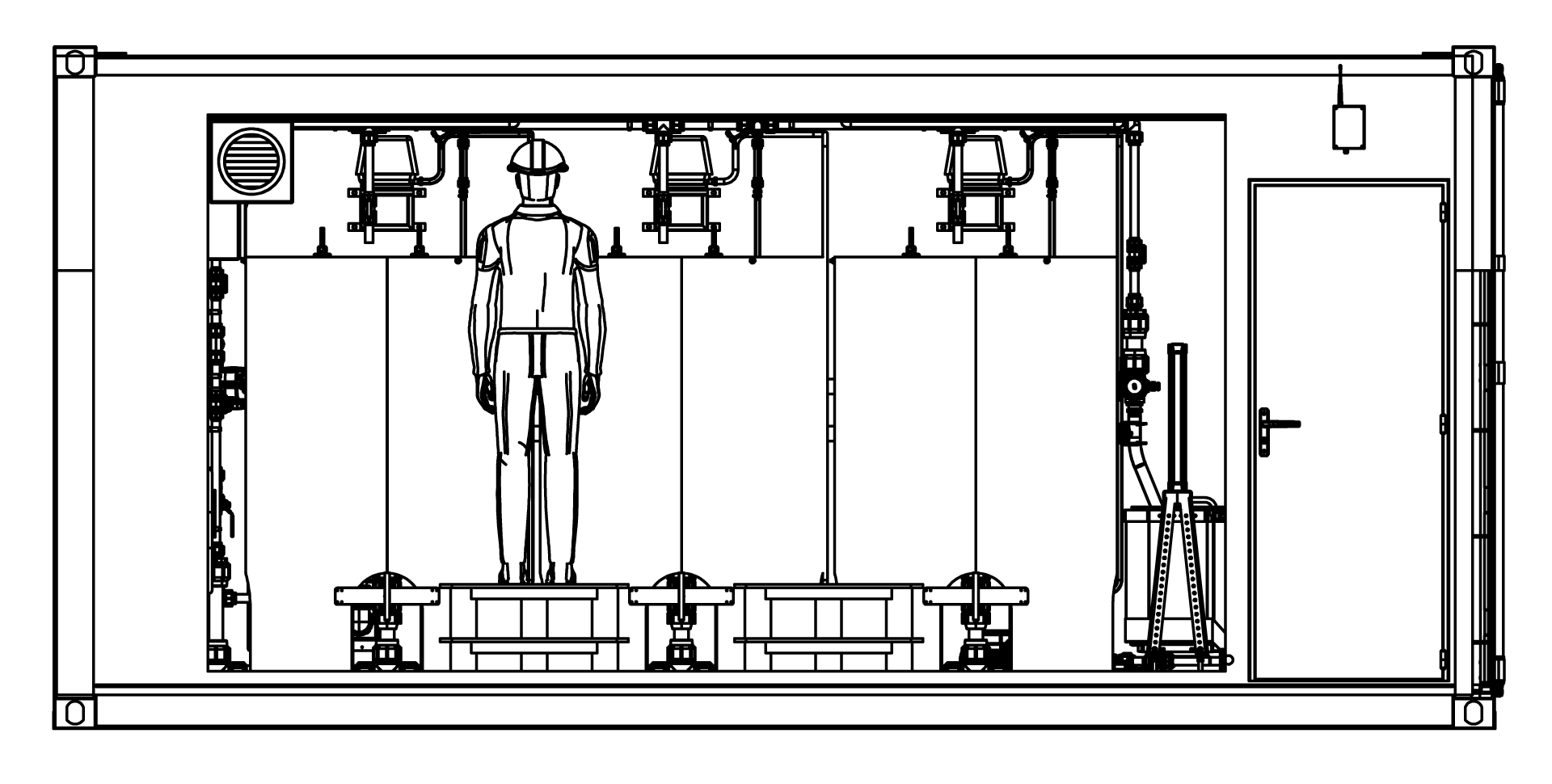

The VALUEFARM Container is a compact, scalable seaweed cultivation system designed for both research and commercial production. It ensures optimal growth conditions and integrates seamlessly with RAS facilities or functions as a stand-alone unit for biotechnology and commercial seaweed production.

Description

This scalable system is available in two standard sizes and offers high-yield, controlled production:

20’ unit with 3 Photo Bio Reactors (PBRs) of 1,200-liter capacity (total: 3,600 liters)

40’ unit with 8 Photo Bio Reactors (PBRs) of 1,200-liter capacity (total: 9,600 liters)

Designed for flexibility and performance, the VALUEFARM Container is a compact, plug-and-play solution for land-based seaweed cultivation. Whether for commercial use or research, it offers consistent output and simple operation in a modular format.

Production capacity: Each PBR yields 5–13 kg of fresh biomass per week at 10% dry weight

Integrated harvesting system with tanks, pumps, and a unique press for easy biomass handling

CE-marked and compliant with EU regulations for work safety and food contact materials

Optional service and maintenance agreements for optimized operation and long-term support

Optional sensor & IoT monitoring of parameters such as temperature, pH, flow, salinity, and real-time biomass growth

A 40’ container unit can produce up to 5.4 tonnes of fresh weight per year (10% dry weight) for a high-performing Ulva strain. The Laboratory Setup or a Feasibility Study can support strain selection or optimization for target compounds such as proteins or polysaccharides.

Your Benefits

The VALUEFARM Container offers stable and predictable yields without weather dependencies. It enables scalable growth, allowing you to start small and expand production over time. With a proven plug-and-play design, the system is easy to install and operate — even without prior experience when paired with our service agreement. The container provides a low-risk path to validate your seaweed business before committing to industrial-scale investments. Each unit can be tailored to maximize your production potential.

Ideal for:

✓ Commercial production

✓ Reliable biomass supply

✓ High quality output

Best suited for:

RAS

Seaweed Grow-out

Biotech

Why choose it:

Plug-and-play modular design with relevant certifications

Works stand-alone or integrated with RAS farms (IMRAS)

Easy to operate and service – no experience required

-

Scalable solutions.

Our technology is based on a scalable and modular concept.

-

Controlled environment.

The containers ensures a controlled environment 24/7.

-

Stable production.

Stable production independent of wind and weather.

-

High quality.

Consistent production of high-quality seaweed.

-

Automation.

High level of automation and easy operation.

Integrating Container-Based Operations with Scalable Production

The VALUEFARM Containers are often combined with the Laboratory Setup when teams want to replicate controlled workflows in a container environment or refine operational routines before scaling up. For projects focused on strain selection or rapid comparative trials, the Laboratory Batch Setup provides an efficient testing platform that feeds directly into container-based cultivation.

When production targets exceed container capacity, groups typically scale into the VALUEFARM Towers for fully controlled pilot-level biomass output.

Specifications

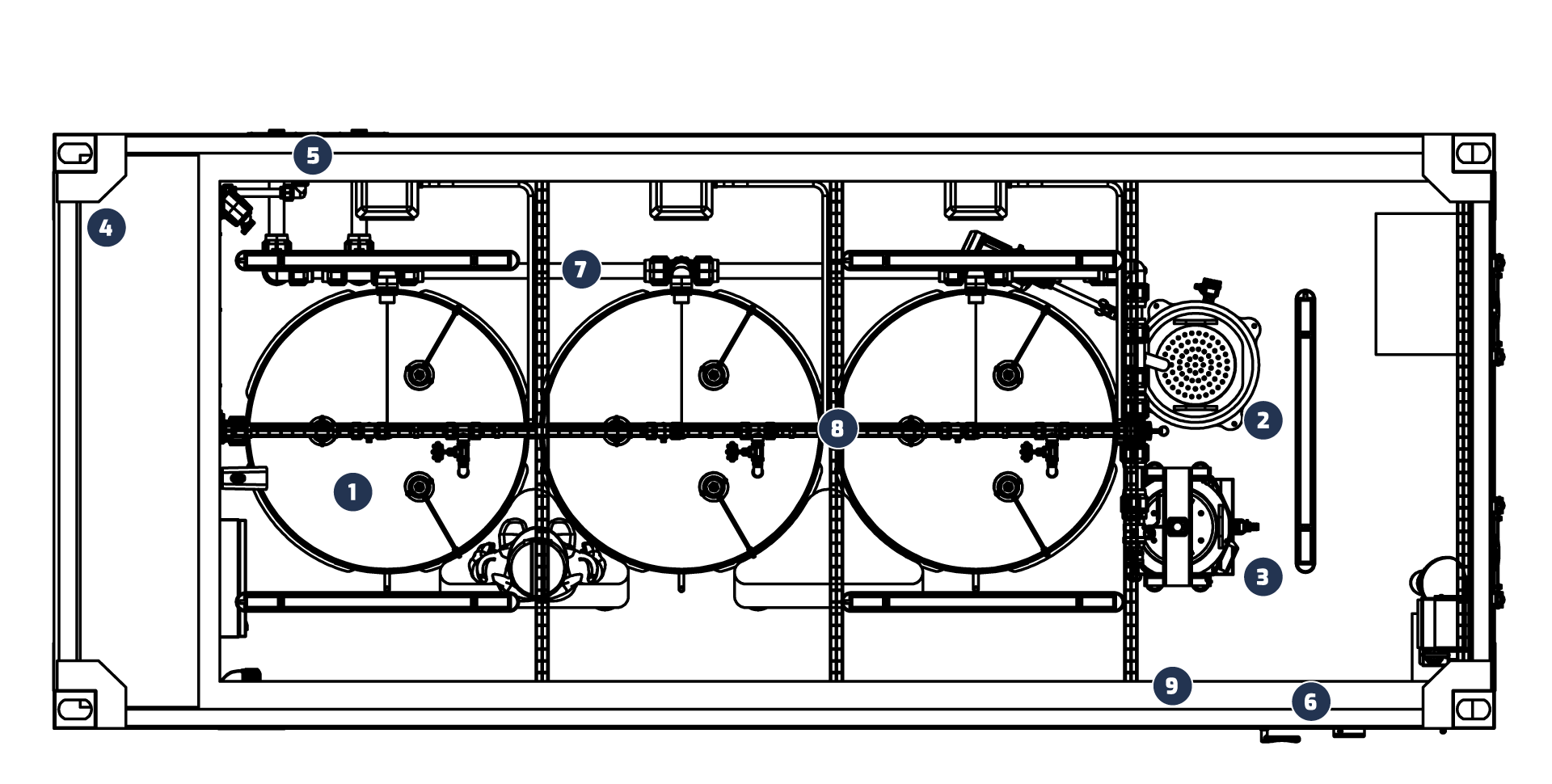

Photo Bio Bioreactors [1]

Harvesting System [2]

Seaweed Pressing Unit [3]

20’ or 40’ High Cube Reefer [4]

Plug and Play Connection Hub [5]

Easy Entrance [6]

Flow Through System [7]

Sensors and monitoring [8]

IoT Control Panel [9]

Our other products/services

Feasibility Study

Unlock the Full Potential of Seaweed Cultivation Before Investing

Our Feasibility Study service provides data-driven insights to help you determine the viability of seaweed production – either at your site or based on your specific compound targets..

Incubator Unit – Single Photobioreactor (PBR)

Compact, Plug-and-Play Cultivation for Experiments, Demonstration & Outreach

This standalone PBR is the most accessible and cost-effective entry point into land-based seaweed cultivation and hatchery activities.